At Spiroid, we’re often asked to provide a high-level overview of how our gearing technologies compare to other right angle solutions such as worms. While it’s easy to make generalizations about one technology versus another, it is usually a fool’s errand unless the comparison is made within the context of a specific application and follows a consistent design focus. Without such context or focus, universal statements comparing one gear technology to another are often misleading, if not downright false.

Case in point: While Spiroid may be perceived as generally having a higher torque capacity than worm gears, any worm gear set can exceed a given Spiroid gear set if parameters such as size or reduction ratios aren’t fixed. In other words, the trade-offs between torque, size, ratio and efficiency are simply too interrelated to ignore for a given comparison.

With all of this in mind, we set out to compare our Helicon right angle gear technology with that of a standard, ANSI/AGMA 6034-B92 worm design. To do this, we reviewed the two technologies through the lens of 3 separate focus areas, each with their own application requirements. The focus areas and respective application requirements were as follows:

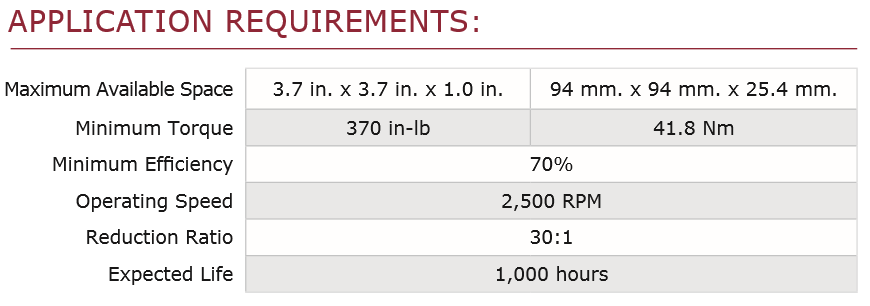

Helicon vs Worm, Design Focus: “Maximize Torque”

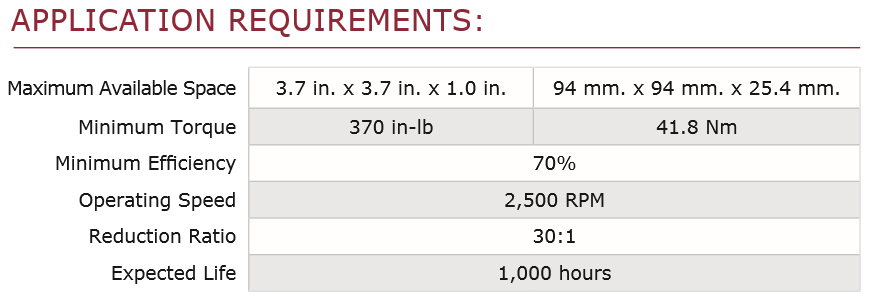

Helicon vs Worm, Design Focus: “Minimize Space Claim”

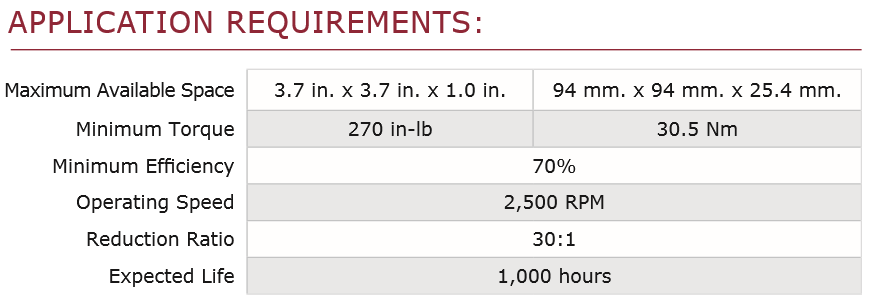

Helicon vs Worm, Design Focus: “Maximize Efficiency”

Of course, since the three focus areas are largely interconnected, we also wanted to see what happens to the other two once a design is optimized. In other words, if our focus is to ‘maximize torque,’ what happens to the ‘space claim’ and ‘efficiency’ of that design, given the defined application requirements?

Would you like to find out how Helicon and worm technologies compare within the context of the 3 applications outlined above?

Take me to a ‘Helicon vs Worm Comparison’ which focuses on MAXIMIZING TORQUE

Take me to a ‘Helicon vs Worm Comparison’ which focuses on MINIMIZING SPACE CLAIM

Take me to a ‘Helicon vs Worm Comparison’ which focuses on MAXIMIZING EFFICIENCY